Our below listed services include a sizable range for textile spinning plants. Our core competency lies in our ability to assist business to optimize operations and maximize revenue through measurable growth and develop a sustainable, competitive advantage through engagement and scientific approach.

Sourcing of vast range of textile fibres like:

- Nylon (1.2D to 3.0D)

- Wool (15.5 to 23.0 Micron)

- Cashmere (15.5/16.5 Micron)

- Linen (normal & bleached)

- Silk

- Mousse fibre (14 dtex 7 28 dtex)

- Cut-metallic (12Micron,1/350”, 40mm in multiple colours) on cotton spinning system for value added products for high-end customers.

- Cotton (Normal, Organic, BCI, Recycled)

- Polyester (0.6D to 15D)

- CDP Polyester

- Sustainable Polyester

- Low Pill Polyester

- Viscose (0.9D to 5.5D)

- Modal, Modal Air, Tencel LF/Tencel A100 & sustainable cellulosic fibres

- Acrylic (0.5.5D to 3.0D & Pilbloc)

Raw Cotton

Raw material (Cotton) procurement mechanism to minimize risk elements and achieve cost economies

Cotton Ginning Projects

Planning, line sequencing and execution

Sourcing

Yarn, Fabric and Accessory/consumables sourcing with wide range of options

Re-structuring

Re-structuring and man-power rationalization through time & motion study for direct cost economies

New Methodology & techniques

Introduce and implement new methodology and techniques for enhanced performance

Plant & machinery maintenance

Efficient plant and machinery maintenance techniques for minimized production interruptions

KPI services

Benchmarking & KPI services

Supply Chain Optimization

Supply Chain Optimization for textile spinning operations

Automation

Automation and upgradation of existing projects

Evaluation of spinning plants

Complete evaluation of spinning plants to improve the bottom-line

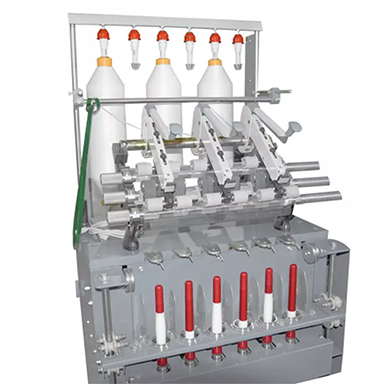

Develope fancy yarn

Know-how to develop specialty/fancy yarn on demand

Lab spinning set-up

Complete lab spinning set-up for pre-sampling and testing of specialty yarn